The lowdown on The TC Bros.

Here is a phone call interview I had with Tyler from the TC Bros Choppers. We talked about some of the new products that they have for sale and how the TC Brothers launched their motorcycle company. We also have some nice pics of XS650’s built by the TC Bros for you to drool over.

Ted: So what was the first product you guys ended up offering for sale?

Tyler: Our very first product was XS650 Forward Controls. We built a bike and back then, when we built that bike, which is probably I don’t know six years ago now, maybe longer now. At the time there was nothing made for them. Nobody was making anything.

Ted: Mm-hmm. It was like ’04. ’03, ’04.

Tyler: Yeah. Yeah, it would have been like ’04, probably.

Ted: Yeah, because I’ve been playing around with the XS since probably 2002. 2002 was my first real bike that I built, and I just remember I was just starting to get in it . . .

Tyler: Back then we built our own one off hardtail, one off forward controls, one off handlebars. We did the whole thing. We were like, “Man, we should try selling these forward controls.” We stuck them on eBay and we received good response so we started doing them for other models.

Ted: What were you doing before that?

Tyler: I worked automotive first. I worked at a crankshaft manufacturing company and did machine fixture designs and process engineering. I’m a mechanical engineer by trade. I’ve got a bachelor’s degree in mechanical engineering. Tim has an associates degree in industrial maintenance and is a machinist/welder by trade. He is one of the most skilled fabricators I have ever worked with. Makes for a pretty good team.

Ted: I started out in engineering (College) before I switched to business.

Tyler: Oh, really that’s cool. I got a business minor.

Ted: Nice.

Tyler: I did get a business minor, but my love was engineering. I also worked at a medical company. I did design, all design there. It was all bent metal welded assemblies and stuff, just like the same stuff I was doing at home with bikes at the time. I designed wheelchairs, hospital beds, stretchers, stuff like that.

Ted: Yeah, that probably helped you a lot getting your first products made.

Tyler: I was already doing our chopper stuff when I was at that last job. But it was definitely good experience. I mean, it related so much to what I was doing here. We just got so busy in the shop that myself and my brother went full time with it. Then we got busy enough to hire some guys working shipping and guys helping with the prototyping and fabrication.

Ted: What’s your most popular product, do you think?

Tyler: XS650 Weld On Hardtail.

Ted: Nice. That’s probably what I would have guessed too.

Ted: Yeah, you’re probably definitely the most widely used hardtail for sure.

Tyler: Yeah we sell quite a few of them. We have always built them ahead of time and kept them in stock so customers do not have to wait for them when they order. Fast service and affordable, quality products has always been our number one priority.

Ted: Yeah, and the Yamaha xs650 has come a long way in the past couple of years. Before, ’02, there was probably only you and maybe Ardcore choppers, I think was started up by then, doing parts for the 650. Now there are tons of parts coming out for the xs650.

Tyler: Oh yeah, they’re acceptable to the general public now. They’re finally getting accepted. I mean, I thought they were cool all along. We were the only people that bothered with them. Everyone else was Harley or nothing.

Ted: Yeah.

Tyler: We had the xs650 as our main motorcycle from day one. Now, another bike we’re prototyping products for is Harley Sportsters. We’re going to do what we do for the xs650 but for Sportsters.

Ted: Nice.

Tyler: That’s our next step.

Ted: Yeah, but the XS 650 market is still pretty new for aftermarket chopper parts.

Tyler: Definitely.

Ted: The Street Tracker market is kind of, it’s pretty old but for custom motorcycles, like hardtail style choppers, the market is really. The thing I don’t think that people really think about is that more XS650s were made than the Triumph. Think of how big the Triumph aftermarket parts is.

Tyler: Oh, yes, it’s amazing. The volume of XS650s out there is huge.

TC Bros. Choppers Blue Collar Bobber

Ted: Blue Collar Bobber, that’s a pretty clean looking bike. How much time and money did you put into it?

Tyler: That’s a good question. I didn’t do my final cost on what everything was. Our cost was pretty low because we make everything for it here. Even buying everything at retail from us it’s very affordable. It’s probably something that somebody can take their 650 and spend $2,000 or less on and create it complete, depending on how much you want to do yourself or how much you want to buy and how elaborate you go on your paint job. The Springer was a substantial chunk of budget. You could build it a lot cheaper without a Springer really because you don’t need the Harley front wheel, brake or rotor. Time, I guess it was built on and off for about two months.

Ted: Yeah, it’s kind of hard to put a time on a build. My bike, if you consider how much time I put into it, I’ve been building it for five years.

Tyler: Gotcha.

Ted: It’s on it’s fourth reincarnation.

Tyler: It was pretty much work done whenever we had a free minute in the shop, I guess, is how this one worked. I mean, it’s whenever you had time between making parts, you’d do a little here and there on the bike.

Ted: Yeah. Yeah, I work on mine, you know, a couple of hours a week. Whenever I have a chance, kind of like go out in the garage and decompress. Screw around with my bike.

Tyler: Yeah.

Ted: Whose bike is the Blue Collar bike anyways? Is it yours or your brother’s?

Tyler: I guess it’s both. It’s the shop’s. The sole purpose of that build was we had added so many more products to our line that we wanted to get a good representation of what everything looked like installed, to take to shows, like Mid-Ohio. So I made it to bring to The Horse Smoke Out and stuff like that. We put that bike together to showcase those products. We wanted to show the average, at-home guy, working in his garage what he could make on a reasonable budget and in a reasonable time frame and actually have something rideable and reliable when it was all done.

Ted: You think you’re going to sell it and start another one?

Tyler: We are working on another one right now.

Ted: Nice.

Tyler: It’s going to have those new “Lane Splitter” bars and some other stuff. It’s going to be more radical looking than what this one was but still very rideable.

Ted: Traditional style.

Tyler: This one was a really traditional Bobber.

Ted: It’s got the ape hangers and the nice two-tone blue white. . .

Tyler: Yeah. This one is classic, our new one is going to be a little more West Coast style. A little bit more edgy, I guess, than what this one was. This was a very traditional build to make a representation of a classic Bobber done with an XS650 with parts that people can go out and purchase rather than having to completely make themselves.

TC bros-xs650 Caferacer

Ted: Right on. What about the Cafe Racer?

Tyler: The Cafe Racer, I guess that was built in about the same amount of time, maybe a little bit less.

Ted: What are the stats on it? What year, and did you do anything with the motor or anything like that?

Tyler: It’s a 1978 frame, stock frame, no real modifications other than powder coating.

Ted: Did you strip it down?

Tyler: Yup, yup, the motor is rebuilt and polished

Ted: You guys have a powder coater?

Tyler: Yes, we powder coat our stuff in-house. The motor’s a 1972 that I had. I have 17 complete XS650s right now. I’ve got various parts and whatnot. It’s just kind of one we put one together. It was a good running ’72 motor and we freshened up the top end anyways and put a cam in it. Other than that, it’s pretty much stock.

Ted: It’s got your rearsets on it?

Tyler: Yup, that’s basically the reason we built it was to showcase the rearsets.

Ted: Where did you score that tail section at?

Tyler: That’s an Omar’s Tail Section.

Ted: Oh. What about the exhaust on it, the 2-Into-1? . . .

Tyler: That’s a MAC 2-Into-1, off the shelf.

Ted: Right on. Do you like it or . . .

Tyler: Yeah. It’s got a good Cafe look. I don’t know if it’s the best performing exhaust made for them, but it definitely runs good with it. It’s jetted right. It’s a good running, good performing bike. It’s got sticky tires on it. The rearsets and the Clubmans really makes it handle. It’s got bronze swingarm bushings in it and tapered bearings in the neck. That is the best dollar for dollar handling improvement you can do to an XS650 that’s still on the swingarm.

Ted: Yeah, I put tapered bearings in my front end too.

Tyler: Well worth doing.

Ted: Definitely. Yeah, . . .

Tyler: They are not anything too rigid from the factory that’s for sure.

Ted: Yeah, you could tighten it up as much as you want, and I still had a little bit of play in the front end with the original ball bearings. Then I switched over to the tapered style and it’s like perfect, super smooth.

Tyler: Yeah. It takes away that high speed death wobble that they get on the stock platform.

Ted: What are like your major plans for TC Bros. as a company? You guys are going to expand into new parts or do you have a lot of new ideas for the xs650?

Tyler: Yeah. We’ve got a lot of new XS650 product that we’re planning on releasing here over the next year. I’m hoping to have all my designs done and everything available for sale as soon as I can. We’ve been watching the trends of what people are building. For example, when we started, nobody wanted mid-controls, everybody wanted forward controls. The mid-controls are really getting popular in a lot of these builds, so we’re doing mid-controls with folding pegs. Bolt-on, complete. Then various other products for them and a lot of universal stuff that we’re coming out with that you can use on a lot of different bikes, like a side mount license plate brackets and all that stuff. I’ve got a really long list of new stuff that I’m working on. Then we’re going to venture into the Sportsters. That will probably be the next major platform that we focus on. Then, basically, all the stuff on it is what we sell.

Ted: Fender you got from your site. A taillight you got from your site. Tires are from your shop.

Tyler: Yup, yup, yup.

Ted: Exhaust is yours. Pegs . . .

Tyler: Yeah, and that exhaust is a prototype of something that’s coming out. The license plate holder is a prototype of something that’s coming out. The brake pivot is as well.

Ted: Handlebars.

Tyler: Those are our 12” Black Apehangers. The rear brake pivot is something that’s a prototype and we’re just about ready to release those. Those will be available real soon. The handlebars are our 12 inch black ape hangers. Take everything down to the cables, the lights, I mean, the chain, everything is all available on our site. We’re trying to become as much of an all-in-one stop as possible.

Ted: Everything you need to put your bike together for a XS.

Tyler: For a 650, yes.

Ted: Nice.

Tyler: We’re getting there, closer and closer. We just keep adding products.

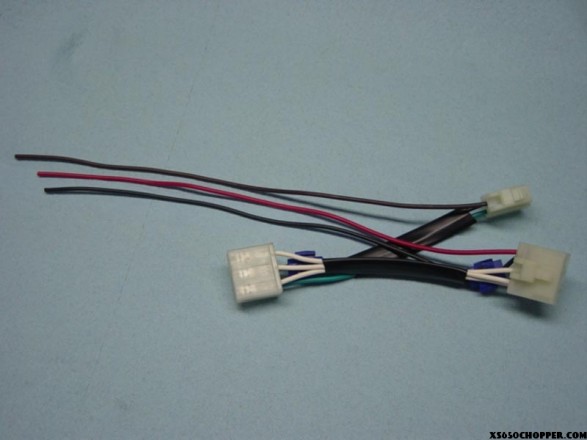

Ted: What about the wiring?

Tyler: Our wire harness that we sell, you take your leads out of your motor, you plug it into the one half of it. The other half of it plugs into your combined regulator and rectifier on the electronic bikes or the separate units on a points bike.

Ted: Yup.

Tyler: Then, on the electronic bikes, we include a harness that goes up to your coil because you’ve got signals that have got to go to that differently than a points bike. It’s got to go from your Ignitor Unit, because it’s an electronic ignition bike. Whereas the points bike, all you’ve got to have is a hot wire going up to your coils.

Ted: Yup.

Tyler: That’s why we’ve got those three different versions. Yamaha had a six wire and seven wire ignition box on the electronic ignition bikes. The six wire ones have a six pin connector shell for them. The seven wire ones had an eight pin connector shell even though only seven of the sockets are used. That’s why we sell two electronic harnesses and one points version.

Ted: Yup.

Tyler: We have worked on that product for, oh man, probably almost two years developing those.

Ted: Yeah, because there’s different wiring schematics for different years and different countries. The Europe and UK models have way different wiring than the US.

Tyler: Yup. The good thing though is to run and charge the bike they are the same. Like just that portion of it between your stator and your voltage regulation and rectification circuit, that stuff is consistent. It’s when you get into lighting and stuff like that, that’s where they varied a lot.

Ted: They have a lot of redundant systems.

Tyler: Oh, it’s crazy how much redundancy is in that stock harness. But yeah, that’s why that harness that we sell only does what you need to run and charge. The lighting and stuff I couldn’t make it plug and play anyways, because, heck, most of the aftermarket lights you buy don’t have a plug on them anyways. What kind of plug would I put on the end of it?

Ted: Right.

Tyler: Lighting is the simple part anyways. It’s a power wire, a fuse, and switching. Most lights are self grounding through the housing.

Ted: Yeah, I get a lot of people ask questions about electrical stuff, I just wish they’d just buy the Yamaha XS650 book (Owners Workshop Manual). When I was trying to figure it out, I was playing around with a permanent magneto and all that.

Tyler: Oh, yeah.

Ted: I just ended up going to the library and getting a stack of books on electronics and motorcycle wiring. Just read them all. Now I can grab a meter and test any part of my bike and I know if it’s faulty or not.

Tyler: Yup, you can check your ohm resistance rating and whatnot. Yeah.

Ted: For me it wasn’t that hard to pick up. But I don’t know maybe . . .

Tyler: It’s not, but everybody is scared of wiring. That’s the main reason we made this kit. This is a foolproof XS650 Chopper Wiring Harness kit. People aren’t going to burn up their stock components. I mean, it will only fit in the components that you need. It will only fit in one way. You know, you can’t cross wires or hook something up backwards. It eliminates that whole stock harness without having to do any cutting or splicing. I actually don’t cut, strip, or crimp my wires by hand either. They are done to OEM quality on production wire harness manufacturing equipment right here in the USA.

Ted: Nice.

Tyler: They’re done very, very well. They’re never going to vibrate or pull out.

Ted: Yeah, I ended up for mine, I ended up using a lot of my components from my original harness. But I just made my own harness with the . . .

Tyler: Gotcha. Yeah, you can do that. Yeah, you can definitely do it. You just got to cut some stuff to do it.

Ted: Yup.

Tyler: This way gives people the option to keep their stock harness all together without molesting it at all. Go stick it on eBay and sell it.

Ted: It’s a lot better for some guys that are just starting out and doing their wiring is probably like the hardest thing for them.

Tyler: Oh, definitely. They’re so intimidated when they see a stock harness. It’s so giant, you know, what do you even need to run it? It scares people in a hurry. By not having to cut your stock one, the stock wiring harness still brings pretty good money on eBay. It gives people an opportunity to sell it without having it cut and whatnot.

Ted: Yup.

Tyler: It funds half their money or more back from what our simplified harness costs. It makes it so cheap and it’s so easy.

Ted: I knew that someone was going to do a wiring harness. After so many e-mails and questions about wiring, I almost considered it myself. I knew that learning about 650 for so long, I knew that it was a lot more complicated than just one wiring harness. There had to be multiple versions or whatever.

Tyler: It took forever. So much research, I mean, we’ve been working on these for a long time. It was very, very time consuming. I’ll have to catch you up on that one sometime. This Blue and White “Blue Collar Bobber”, that’s what I wanted to stress is that we wanted to show what somebody can do on a budget and have something rideable, fun, and reliable. That’s the thing I wanted to show more than anything. We could build something extremely radical if we wanted to. I see so many bikes that guys build with stuff that really makes for a “trailer queen” in a hurry. They start taking stuff off that, yeah, you know, it definitely adds to the looks, but you lose rideability so fast and it creates serious issues. Ground clearance, brakes, stuff like that, where, you know, say what you want, but if you’re really looking to put some miles on your bike, two and half inches of ground clearance and no front brakes and whatnot, well you know what I mean.

Ted: What’s next?

Tyler: The future of TC Bros Choppers all rests on us maintaining good service and quality products for affordable prices. We always want to cater to the “do it yourself” builder who would rather turn his own wrenches and build something unique than go to the dealership and get a factory bike. We just want to keep making our production methods more efficient in order to free up myself and my brother to keep developing more and better products. That’s where we believe we can really grow. I am just glad that there are bikes like the XS650 that have such a loyal following of people who love to customize them, and there are great places like your site to showcase them at.

Ted: Thanks Man.