This poor xs650 sat uncovered in the elements of Washington State so you can imagine just how oxidized and rusted it was. On second thought maybe you can’t imagine how bad it was…the spokes had to be cut out of the oxidized aluminum rim, the old Dunlop tires(possibly OEM)had to be cut off of the rim, once the stainless steel wire in the bead was cut(what a bitch)the antiquated dry and cracked rubber finally stripped off the rim. Then the same procedure was done on the front wheel.

The next venture was to try and polish the old oxidized rims so I worked on them for 3 days ( talk about the devils dirt) and it took another 3 days for my hands to get clean anyway the shined up pretty good, the 65mph shine, there’s still a few pitts here and there, we’ll just call that” patina.”

The rims now have new Dunlop K-70’s, both front and rear hubs are black with powder blue inside.

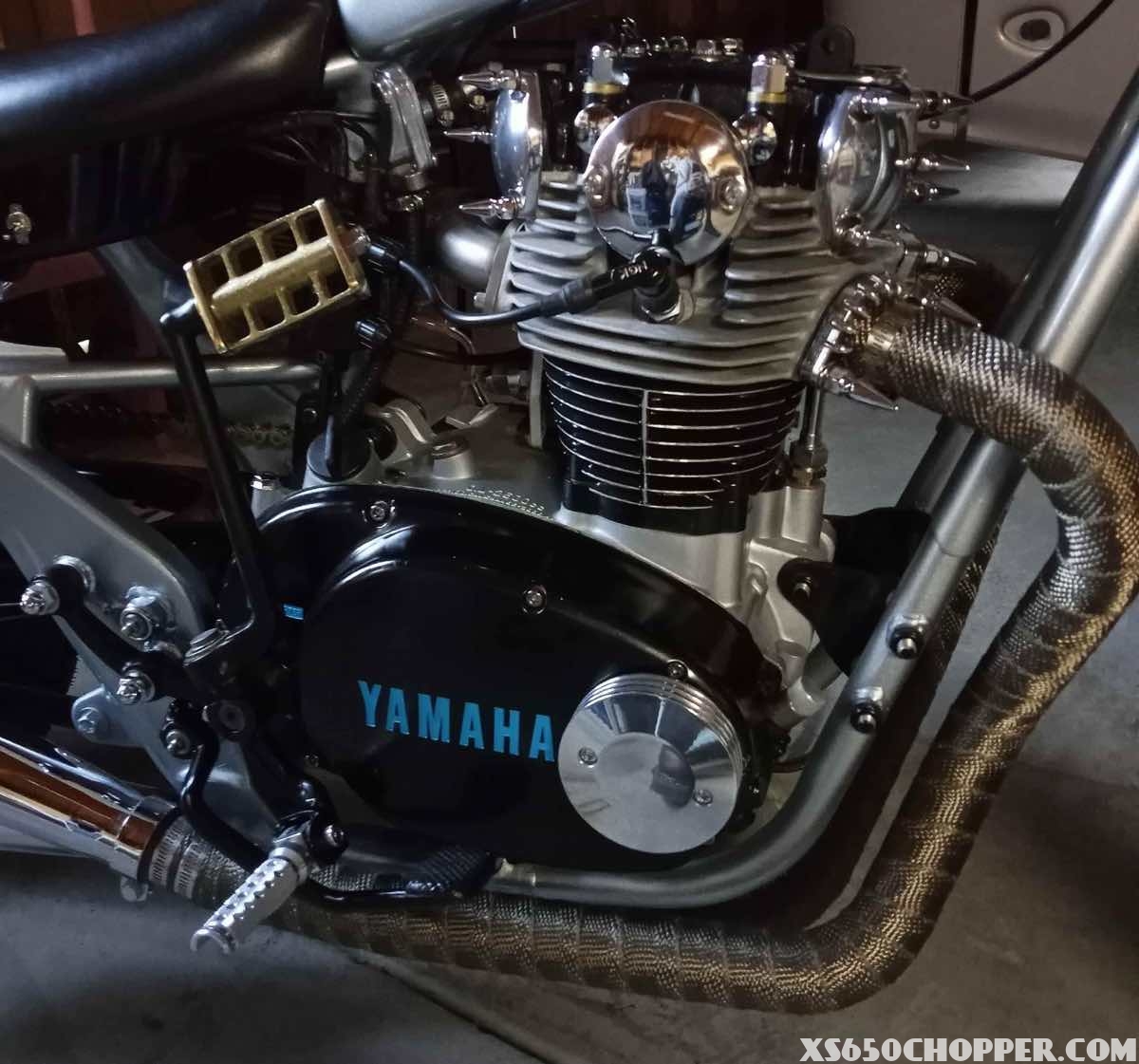

Once the motor was out of its cage, the frame was stripped of all unnecessary tabs, brackets, etc. The seat pan was dropped 3 inches, the swingarm stretched 2 inches, steering head recieved new gussets and the top of the down tubes molded in the ” old school way”). The forks were rebuilt with new seals and lowered 2 inches, fork covers were installed to the tops. Lowers were shaved and blasted then painted black with Transtar 2 in 1Gloss finish #4663.This paint is designed for plastic bumpers on cars and it works great over blasted aluminum or stainless steel, the sparkle you see after blasting can be seen after the paint is applied and it looks like metalic black. It is also very durable and doesn’t scratch easily.

Actually (pretty cool) try it you’ll like it. All of the aluminum parts on this beast were blasted with coal slag 40/80 grit. I rebuilt a Harbor Freight sand blaster with all new ball valves and a brass nozzle with a ceramic tip.

The front wheel was treated with a new disc and caliper with a thin braided stainless steel break line. Controlls up front are all new with a 5 inch halogen headlight and 2 inch speed-0-meter. The seat/Cowell is made of fiberglass whith black leather and faux snaps. The shocks are

12 1/2 inch.( cheap ).

Tailight is LED and turnsignals are LED also. Electrical is under the seat in a fiberglass box with a 4cell antigravity battery, blinker and fuse block.

The gas tank is fiberglass it had a flat bottom, I cut the bottom out and added 2inches to the front and 1inch to the rear with a tunnel to go over the frame. All paint was done by me.

Now for the good part….

The heart of this beast had 2 bent exhaust valves which explains why adjusting the cam chain tensioner is important. Once I found the bent valves the motor needed extensive care.

So down the rabbit hole I went, the 3rd pinion gear was bad, it was replaced and while I was there I added a 5th gear overdrive.

The motor was treated with new bearings and seals, new stock pistons and rings do the pumping, new bronze valve guides with Kibblewhite valves do the breathing in and out and the hi-performance cam operates them. The juice comes from a 36mm Mikuni on a one into two manifold, exhaust is handled by 1 5/8 inch ascott pipes. Exhaust Port Optimizers and Torque Peak Optimizers were added then wrapped up with titanium exhaust wrap finished off with 17 inch reverse cone mufflers.

Charging the electrical system is done by PMA, electronic ignition makes the sparks.

This “”Beast”” was built in a barn in about 3 years.

Hope everyone enjoys this as much as I have.

Oh yea, it runs like a raped ape on bath salts…

Submitted by William Ghent